This facility was made possible by grant support from the W.M. Keck Foundation, the National Science Foundation, and the Geology Foundation of the University of Texas at Austin. Additional funding was provided by the College of Natural Sciences and College of Liberal Arts at the University of Texas at Austin.

Since 1999, UTCT has been a national shared multi-user facility supported by the Instrumentation and Facilities Program of NSF’s Earth Sciences (EAR) directorate. As of 2023 UTCT is a Planetary Science Enabling Facility supported by NASA’s Planetary Science Enabling Facilities program.

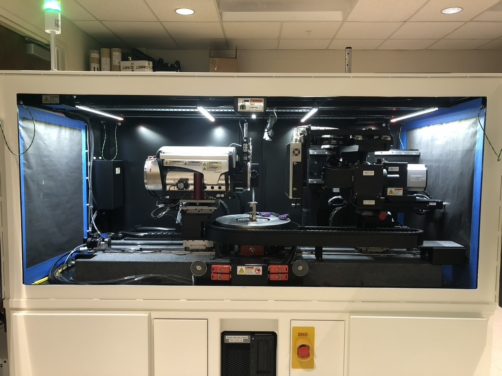

NSI System

The NSI scanner comprises two X-ray sources that share a 2048×2048 Perkin Elmer flat-panel detector within a single radiation-safety enclosure. One is a 225-kV Feinfocus microfocal source designed to acquire ultra-high-resolution data on small objects that can be penetrated by relatively low-energy X-rays (70 kV to 225 kV; maximum spatial resolution ~10 microns). The ability of the microfocal source to provide a stable X-ray output even at low mean energies, combined with the sensitivity of the flat-panel detector, permits excellent discrimination among materials of similar attenuation. The second X-ray source is a 450-kV GE Titan capable of imaging larger or denser objects that require more highly penetrating X-rays (200 kV to 450 kV; maximum spatial resolution ~750 microns). The detectors on the panel can be ‘binned’ for a faster, but lower resolution, acquisition. Scan durations range from a few minutes to hours.

The NSI scanner comprises two X-ray sources that share a 2048×2048 Perkin Elmer flat-panel detector within a single radiation-safety enclosure. One is a 225-kV Feinfocus microfocal source designed to acquire ultra-high-resolution data on small objects that can be penetrated by relatively low-energy X-rays (70 kV to 225 kV; maximum spatial resolution ~10 microns). The ability of the microfocal source to provide a stable X-ray output even at low mean energies, combined with the sensitivity of the flat-panel detector, permits excellent discrimination among materials of similar attenuation. The second X-ray source is a 450-kV GE Titan capable of imaging larger or denser objects that require more highly penetrating X-rays (200 kV to 450 kV; maximum spatial resolution ~750 microns). The detectors on the panel can be ‘binned’ for a faster, but lower resolution, acquisition. Scan durations range from a few minutes to hours.

The system is highly flexible and can operate using several scanning modalities based on specimen composition and geometry and research objectives. In all cases the ultimate resolution is determined by geometric magnification (i.e., the position of the specimen relative to the X-ray source and the flat-panel detector) and by the X-ray focal spot size. The scanner is capable of the following protocols: rotate-only, helical, SubpiX, and MosaiX. The latter two were made possible by an NSI system upgrade completed in 2019 (NSF EAR-1725196) that enabled a detector shift, allowing greater resolution for a particular field of view or larger objects to be imaged (see below).

Scanning modalities:

Rotate-only scanning rotates the specimen on a turntable while acquiring X-ray projections that are subsequently reconstructed into a CT volume. This is a relatively low-overhead means of scanning and is limited by geometric magnification on the detector (imaged area from ~2 x 2 cm to ~36 x 36 cm). The geometric resolution is determined by the maximum dimension of the scanned volume (e.g., a 4 X 4 X 8 cm object can yield a spatial resolution of ~40 microns).

Helical scanning translates the rotating turntable vertically across the detector field while gathering X-ray projections. Our system is capable of scanning up to ~75 cm vertical throw in helical mode. This mode is used when higher resolution is required for a high-aspect-ratio specimen (e.g., a core or column). The geometric resolution is determined by the diameter of the scanned volume (e.g., a 4 X 4 X 8 cm object can yield a spatial resolution of ~20 microns).

SubpiX uses motors to sequentially shift the flat panel detector by a fraction of a pixel in X and Y, scanning four volumes that are stitched together as X-ray projections. This doubles resolution, and generates a volume that is 8X larger than a corresponding ‘rotate only’ scan (e.g., a 4 X 4 X 8 cm object yields a spatial resolution of ~20 microns). This scanning mode is advantageous for high-resolution imaging of a larger volume, but takes a proportionately longer time to acquire.

MosaiX scanning shifts the detectors to acquire objects larger than the detector field of view (~36 cm x 36 cm) based on the specimen dimensions. This permits a scan volume of up to ~45 cm diameter X ~75 cm height. The scan time is determined by the number of subvolumes required to capture the entire volume.

Zeiss Xradia 620 Versa

Our Zeiss Xradia 620 Versa scanner came online in January 2020 (NSF EAR-1919700). It replaced our Xradia MicroXCT 400, acquired in 2008, which was UTCT’s first cone-beam scanner. The 620 Versa provides substantial improvements in resolution, data quality, and range of imaging capabilities over the old instrument. Feature detectability now ranges down to 0.5 µm (was 1.5 µm) and voxel size down to ~0.04 µm. The 620 Versa’s X-ray source ranges from 30 to 160 kV (was 40-150 kV) and up to 25W (was 10W), the latter providing for greater signal through samples at higher energies over shorter periods of time with no reduction in resolution. Its flat-panel detector provides substantial overlap with the NSI system in terms of resolution, but affords lower-energy scanning for greater differentiation between materials that attenuate X-rays similarly, as well as automated dual-energy scanning. Incorporating optical as well as geometric magnification, the 620 Versa can acquire small subvolumes within larger samples at true resolution. Between the flat-panel and 0.4X, 4X, 20X and 40X detector objectives, the Versa can image objects ranging from ~14 cm across to <1 mm.

Our Zeiss Xradia 620 Versa scanner came online in January 2020 (NSF EAR-1919700). It replaced our Xradia MicroXCT 400, acquired in 2008, which was UTCT’s first cone-beam scanner. The 620 Versa provides substantial improvements in resolution, data quality, and range of imaging capabilities over the old instrument. Feature detectability now ranges down to 0.5 µm (was 1.5 µm) and voxel size down to ~0.04 µm. The 620 Versa’s X-ray source ranges from 30 to 160 kV (was 40-150 kV) and up to 25W (was 10W), the latter providing for greater signal through samples at higher energies over shorter periods of time with no reduction in resolution. Its flat-panel detector provides substantial overlap with the NSI system in terms of resolution, but affords lower-energy scanning for greater differentiation between materials that attenuate X-rays similarly, as well as automated dual-energy scanning. Incorporating optical as well as geometric magnification, the 620 Versa can acquire small subvolumes within larger samples at true resolution. Between the flat-panel and 0.4X, 4X, 20X and 40X detector objectives, the Versa can image objects ranging from ~14 cm across to <1 mm.

Expanding beyond standard X-ray CT capabilities, UTCT’s 620 Versa is equipped for X-ray diffraction computed tomography (DCT), which determines the 3D distribution of crystallographic orientations in a solid by detecting and interpreting diffraction spots and tracing them back to their point of origin. It is the first non-synchrotron instrument to offer this capability, which has tremendous potential especially in the geological and materials sciences for sufficiently small samples (< 2 mm). The 620 Versa also is equipped with a modular base that will accept a range of experimental cells for scanning samples under controlled environmental conditions such as temperature and pressure, allowing samples to be imaged at simulated subsurface conditions.

Digital Image Analysis Laboratory

Special hardware and software — and a repository of specialized technical expertise — are required in order to extract full scientific value from the a CT data volume. Because data volumes for 3D reconstruction are generally very large (ranging from ~2 gigabytes for a single volume of 1024² pixel images to ~8 gigabytes for a single volume of 2048² images), their manipulation requires high-end computational resources capable of managing and rapidly processing immense amounts of data. Visualization often relies upon 3D renderings of specimens, and usually benefits from the ability to render some portions of the specimen (i.e., those that occupy a specified range of densities and thus a particular range of grayscale values) as transparent or semi-transparent, to enhance different features of scientific interest (e.g., emu embryo, garnet porphyroblasts). Viewing these renderings and interactively modifying them is essential, enabling a user to examine the digital version of the specimen at any arbitrary viewing angle, or cut a virtual section through any point in any orientation (e.g., Herrerasaurus). Animations of sequential views at successive equally spaced angles, simulating rotation of the specimen about an arbitrary axis, are often the best means of examining relationships among features (various examples may be viewed on our examples page for CT applications). For large CT datasets, these advanced visualizations require fast hardware running specialized software, many of them demanding a surprising degree of proficiency with the software to accomplish one’s desired aims. Because systems capable of meeting these exacting requirements, and the expertise to use them effectively, are often not available to potential users at their home institutions, an adjacent computer laboratory dedicated to the processing of the digital images acquired from our CT scanners is a vital adjunct. The digital imageanalysis laboratory is able to provide services to outside investigators and convert data into formats easily integrated into their existing research programs. The same experienced research scientists responsible for day-to-day operation of the CT scanners also staff the image-analysis laboratory, ensuring proper interpretation of the data and maintenance of its integrity throughout processing.

Special hardware and software — and a repository of specialized technical expertise — are required in order to extract full scientific value from the a CT data volume. Because data volumes for 3D reconstruction are generally very large (ranging from ~2 gigabytes for a single volume of 1024² pixel images to ~8 gigabytes for a single volume of 2048² images), their manipulation requires high-end computational resources capable of managing and rapidly processing immense amounts of data. Visualization often relies upon 3D renderings of specimens, and usually benefits from the ability to render some portions of the specimen (i.e., those that occupy a specified range of densities and thus a particular range of grayscale values) as transparent or semi-transparent, to enhance different features of scientific interest (e.g., emu embryo, garnet porphyroblasts). Viewing these renderings and interactively modifying them is essential, enabling a user to examine the digital version of the specimen at any arbitrary viewing angle, or cut a virtual section through any point in any orientation (e.g., Herrerasaurus). Animations of sequential views at successive equally spaced angles, simulating rotation of the specimen about an arbitrary axis, are often the best means of examining relationships among features (various examples may be viewed on our examples page for CT applications). For large CT datasets, these advanced visualizations require fast hardware running specialized software, many of them demanding a surprising degree of proficiency with the software to accomplish one’s desired aims. Because systems capable of meeting these exacting requirements, and the expertise to use them effectively, are often not available to potential users at their home institutions, an adjacent computer laboratory dedicated to the processing of the digital images acquired from our CT scanners is a vital adjunct. The digital imageanalysis laboratory is able to provide services to outside investigators and convert data into formats easily integrated into their existing research programs. The same experienced research scientists responsible for day-to-day operation of the CT scanners also staff the image-analysis laboratory, ensuring proper interpretation of the data and maintenance of its integrity throughout processing.